The Stihl MS170 parts diagram PDF is an essential resource for understanding and maintaining your chainsaw․ It provides detailed exploded views of components, ensuring accurate repairs and replacements․

1․1 Overview of the Stihl MS170 Chainsaw

The Stihl MS170 is a lightweight, compact chainsaw designed for domestic use․ It features a powerful 2-MIX engine, offering excellent fuel efficiency and reduced emissions․ The saw is ideal for cutting firewood, pruning, and small-scale logging․ With its ergonomic design and easy-to-use controls, the MS170 is popular among homeowners and professionals alike․ Understanding its components through the parts diagram is crucial for maintenance, repairs, and ensuring optimal performance․ This guide provides a detailed breakdown of the chainsaw’s key features and components․

1․2 Importance of the Parts Diagram

The Stihl MS170 parts diagram is a vital tool for users, providing a visual and detailed breakdown of every component․ It helps identify parts, understand their assembly, and locate wear or damage․ This diagram is essential for DIY repairs, ensuring that replacements are accurate and compatible; Regular maintenance and troubleshooting rely heavily on this resource, making it indispensable for maintaining the chainsaw’s performance and longevity․ By referencing the parts diagram, users can ensure their MS170 operates safely and efficiently, preserving its value over time․

Stihl MS170 Parts Diagram Explained

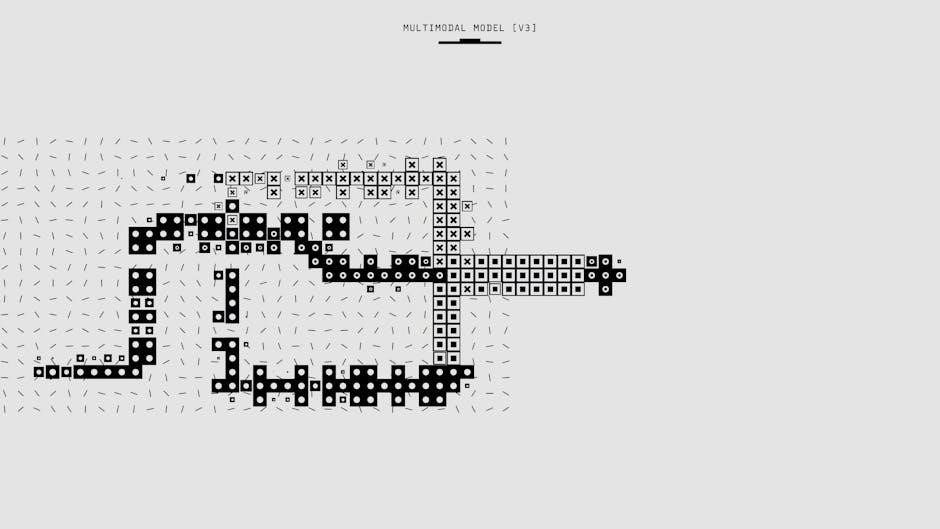

The Stihl MS170 parts diagram provides a detailed, visual breakdown of the chainsaw’s components, including exploded views and identification of key parts for maintenance and repair․

2․1 Understanding the Layout of the Diagram

The Stihl MS170 parts diagram is organized into sections, each highlighting specific components․ It uses exploded views to show how parts fit together, making it easier to identify and locate items like the engine housing, cylinder, and muffler․ The layout is logical, with numbered parts corresponding to a comprehensive list․ This structure helps users navigate the diagram efficiently, whether they’re searching for a particular component or planning a repair․ The clear visuals and detailed labels ensure clarity and precision for maintenance tasks․

2․2 Key Components and Their Identification

The Stihl MS170 parts diagram identifies major components like the engine housing, cylinder, muffler, and carburetor․ Each part is labeled with a number and description, corresponding to the exploded views․ The chain brake and tensioning system are also highlighted, along with the handlebar and controls․ The diagram uses clear visuals to differentiate between wearable parts and permanent components, helping users quickly locate items for maintenance or repair․ This detailed identification system ensures accuracy when referencing the catalog or ordering replacements․

Major Components of the Stihl MS170

The Stihl MS170 includes engine housing, cylinder, muffler, carburetor, chain brake, handlebar, exhaust system, and fuel tank․

3․1 Engine Housing and Crankcase

The engine housing and crankcase are critical components of the Stihl MS170, providing structural support and protection for the internal engine mechanisms․ These parts are detailed in the PDF diagram, showcasing their assembly and integration with other systems․ The engine housing (part number 1130 020 3033) encases the crankshaft and pistons, while the crankcase ensures proper engine operation․ The diagram highlights these components, enabling users to identify and maintain them effectively for optimal performance and longevity of the chainsaw․ Regular inspection is essential to prevent damage․

3․2 Cylinder and Piston Assembly

The cylinder and piston assembly is a vital part of the Stihl MS170, responsible for the engine’s combustion process․ The PDF diagram provides a detailed view of this assembly, including the cylinder (part number 1130 791 4901) and piston․ These components work together to generate power, with the piston moving within the cylinder to drive the chainsaw․ Proper maintenance, as outlined in the diagram, ensures efficient performance and prevents wear․ Regular inspection and timely replacements are crucial to maintain the engine’s functionality and overall efficiency․

3․3 Muffler and Exhaust System

The muffler and exhaust system of the Stihl MS170 play a crucial role in reducing noise and emissions․ The parts diagram PDF highlights components like the muffler (part number 1130 791 4901) and exhaust manifold․ These parts are essential for directing exhaust gases away from the operator while ensuring compliance with environmental standards․ Regular inspection and cleaning of the muffler are recommended to prevent clogging and maintain optimal performance․ Referencing the diagram simplifies identification and replacement of worn or damaged parts, ensuring the chainsaw operates efficiently and safely․ Proper maintenance extends the lifespan of these critical components․

3․4 Carburetor and Fuel System

The carburetor and fuel system are vital for the Stihl MS170’s performance․ The parts diagram PDF details components like the carburetor, fuel lines, and tank․ Regular maintenance, such as cleaning or replacing the air filter and checking for fuel leaks, ensures proper function․ The carburetor’s correct adjustment, as outlined in the manual, is essential for optimal engine performance․ Users can refer to the diagram for disassembly and troubleshooting, making repairs more efficient․ Proper care of these components ensures reliable operation and extends the chainsaw’s lifespan․

3․5 Chain Brake and Tensioning System

The chain brake and tensioning system ensures safe and efficient operation of the Stihl MS170․ The parts diagram PDF details components like the hand guard, brake lever, and spring․ Proper tensioning is critical for optimal chain performance, and the diagram guides users through adjustments․ Regular inspection of brake components prevents accidents․ The exploded view helps identify worn parts, such as the chain tensioner or brake pad, for timely replacement․ This system is essential for maintaining safety and functionality during cutting operations․

3․6 Handlebar and Control Mechanisms

The handlebar and control mechanisms are vital for maneuverability and operator control․ The PDF diagram highlights components like the handlebar frame, throttle trigger, and safety lever․ These parts ensure precise control over the saw’s functions․ The exploded view aids in identifying and replacing worn elements, such as the grip or lever, ensuring smooth operation․ Regular inspection of these components is crucial for maintaining handling performance and safety․ The diagram simplifies maintenance by providing a clear visual reference for repairs and adjustments․

The Stihl MS170 parts diagram PDF is a crucial tool for maintenance, enabling users to identify and replace worn components efficiently․ It ensures accurate repairs․ The Stihl MS170 parts diagram PDF helps users identify wear and tear parts by highlighting components prone to damage․ It provides clear visuals of chains, bars, and sprockets, allowing for early detection of worn items․ Regular inspection using the diagram ensures proactive maintenance, preventing costly repairs․ By referencing the exploded views, users can pinpoint areas needing attention, such as the chain brake, muffler, and carburetor, ensuring optimal performance and longevity of the chainsaw․ The Stihl MS170 parts diagram PDF is crucial for scheduling maintenance and replacements․ It outlines the frequency of checks for critical components like the chain, bar, and air filter․ Regular lubrication of moving parts, such as the chain and sprocket, is emphasized to prevent premature wear․ The diagram also highlights when to replace wear items, ensuring the chainsaw operates safely and efficiently․ By following the maintenance schedule, users can extend the lifespan of their tool and maintain its performance․ Always consult the diagram for accurate part numbers during replacements․ The Stihl MS170 parts diagram PDF aids in diagnosing common issues like poor engine performance or chain malfunction․ By referencing the exploded views, users can identify faulty components such as air filters, spark plugs, or fuel lines․ Regular checks for wear on parts like the chain, bar, and sprocket are essential․ The diagram also helps locate issues with the muffler or carburetor, ensuring quick resolutions․ Always refer to the parts list for accurate replacements and follow safety guidelines during troubleshooting to avoid further damage or injury․ The Stihl MS170 parts diagram PDF provides detailed guidance for repairing and replacing components, ensuring accurate and safe maintenance using genuine Stihl parts․ The Stihl MS170 parts diagram PDF provides detailed step-by-step repair instructions, guiding users through disassembly, component replacement, and reassembly․ Each step is accompanied by visual references from the exploded view, ensuring precise identification of parts․ Users can locate specific components using the diagram’s numbering system, cross-referenced with the parts catalog․ Instructions emphasize the use of genuine Stihl parts for reliability and safety․ Common repairs, such as replacing the chain brake or fuel system components, are clearly outlined․ Always follow safety precautions, like disconnecting the spark plug, before starting any repair․ Regular testing post-repair ensures proper functionality․ To repair your Stihl MS170, essential tools include screwdrivers (Phillips and flathead), Torx keys, and wrenches․ Pliers and a spark plug tester may also be necessary․ Download the Stihl MS170 parts diagram PDF for detailed exploded views, ensuring accurate identification of components․ Refer to the parts list for exact part numbers when ordering replacements․ Genuine Stihl parts are recommended for compatibility and safety․ Always follow torque specifications and safety guidelines provided in the manual or diagram․ Proper tools and resources ensure efficient and reliable repairs․ When performing repairs on your Stihl MS170, always wear protective gear, including gloves and safety glasses․ Disconnect the spark plug to prevent accidental start-ups․ Handle sharp components like the chain and bar with extreme care․ Use the parts diagram to identify components accurately and avoid misassembly․ Check for worn or damaged parts before reassembly․ Follow all safety guidelines in the operator’s manual; Ensure proper torque specifications are met․ Never compromise on safety to prevent accidents and ensure reliable performance․ To maintain your Stihl MS170’s performance, order genuine parts from authorized dealers․ Use the parts diagram to locate and verify part numbers before purchasing online․ To ensure authenticity, locate genuine Stihl dealers through the official Stihl website or authorized local retailers․ Verify their certification to avoid counterfeit parts․ Use the parts diagram to identify specific components and confirm availability before visiting․ This ensures you receive high-quality products tailored to your MS170 model․ Additionally, online marketplaces like the official Stihl store or trusted sellers offer validated parts, maintaining performance and safety standards․ Always cross-reference part numbers from the diagram with the dealer’s inventory for accuracy․ Ordering parts online for your Stihl MS170 is convenient and efficient․ Use the parts diagram to identify the exact components needed, then visit the official Stihl website or authorized dealers like LS Engineers․ Search by model number or part number to ensure accuracy․ Many retailers offer online catalogs and exploded views, making it easy to select the correct items․ Verify the authenticity of the dealer to avoid counterfeit parts․ Once ordered, parts are typically shipped directly to your location, ensuring quick access for repairs or maintenance․ Always double-check compatibility with your MS170 model before finalizing your purchase․ Verifying part numbers is crucial when ordering replacements for your Stihl MS170․ Use the parts diagram to cross-reference each component’s number, ensuring accuracy․ Official sources like the Stihl website or authorized dealers provide reliable part numbers․ Double-check against the exploded view diagrams to confirm compatibility․ Enter the part number directly on the retailer’s website to avoid mismatches․ This step ensures you receive the correct part, saving time and preventing installation issues․ Always refer to the latest catalog or manual for updated part information․ The exploded view of the Stihl MS170 provides a detailed visual breakdown of its components․ This diagram is essential for understanding assembly and disassembly processes, aiding in repairs․ The Stihl MS170 parts diagram PDF offers a visual representation of components through detailed exploded views․ These diagrams illustrate how parts are assembled and connected, making it easier to identify and locate components․ Each part is numbered and labeled, providing clarity for users․ This visual guide is particularly useful for technicians and DIY enthusiasts, as it simplifies the process of understanding the chainsaw’s structure․ By referencing these diagrams, users can better comprehend the relationships between components, aiding in repairs and replacements․ The Stihl MS170 parts diagram PDF includes a detailed assembly and disassembly guide, providing step-by-step instructions for professionals and DIY enthusiasts․ The exploded views help users understand how components fit together, ensuring proper reassembly․ This guide is essential for identifying parts and their relationships, minimizing errors during repairs․ By following the diagram, users can safely disassemble and reassemble the chainsaw, maintaining its performance and longevity․ This visual aid is invaluable for anyone looking to service or repair their Stihl MS170 effectively․ The Stihl MS170 parts diagram PDF features a comprehensive parts list and catalog, detailing part numbers, descriptions, and exploded views for easy identification and ordering․ The comprehensive parts catalog in the Stihl MS170 parts diagram PDF provides a detailed listing of all components, including part numbers, descriptions, and diagrams․ This catalog is organized by sections, such as engine housing, cylinder, muffler, and chain brake systems, making it easy to locate specific parts․ Each item is cross-referenced with exploded views, allowing users to visualize assembly and disassembly processes․ This resource is invaluable for maintenance, repairs, and ensuring genuine Stihl parts are used for optimal performance and safety․ The cross-reference guide in the Stihl MS170 parts diagram PDF helps users identify compatible or alternate parts by referencing part numbers, descriptions, and diagrams․ This guide is particularly useful for ensuring compatibility when ordering replacement parts or upgrading components․ It aligns with the comprehensive catalog, making it easier to navigate and verify part numbers for accuracy․ This feature minimizes errors during repairs and ensures that only genuine Stihl parts are used for optimal performance and safety․ The operator’s manual provides essential safety tips, pre-operation checks, and storage guidelines for the Stihl MS170․ Adhering to these ensures safe and effective use of the chainsaw․ Always wear protective gear, including gloves, safety glasses, and sturdy footwear․ Ensure a firm grip on the handlebar and maintain proper posture to avoid fatigue․ Keep loose clothing tied back and avoid distractions․ Never operate the chainsaw near flammable materials or in enclosed spaces․ Regularly inspect the chain for sharpness and damage, and ensure the muffler is free of debris․ Store the chainsaw in a dry, secure location out of children’s reach․ Follow all guidelines in the operator’s manual for safe operation․ Before starting the Stihl MS170, always perform a thorough pre-operation inspection․ Check the chain for sharpness and proper tension, ensuring it’s not loose or damaged․ Inspect the muffler and exhaust system for blockages or debris․ Verify the fuel system for leaks, paying attention to the tank cap, hoses, and fuel pump․ Ensure all controls, such as the chain brake and throttle, function correctly․ Refer to the parts diagram to locate and inspect critical components․ A well-maintained chainsaw ensures safe and efficient operation․ Proper storage and transportation of your Stihl MS170 are crucial to maintain its performance and longevity․ Always clean the chainsaw thoroughly before storage, ensuring no debris remains․ Store it in a dry, secure location away from direct sunlight and moisture․ Use a protective cover to prevent dust accumulation․ When transporting, secure the chain with a protective bar cover and ensure the saw is tightly fastened to prevent movement․ Refer to the parts diagram for specific components needing extra care during storage or transport․ Following these tips ensures your MS170 remains in optimal condition for future use․ Access the official Stihl website or authorized dealers to download the MS170 parts diagram PDF․ Ensure authenticity by verifying the source and file integrity․

The Stihl MS170 parts diagram PDF is available for download directly from Stihl’s official website or through authorized Stihl dealers․ These sources ensure authenticity and accuracy, providing detailed exploded views and parts lists․ Additionally, trusted online marketplaces and parts catalogs, like LS Engineers, offer verified PDFs for download․ Always verify the source to avoid counterfeit or incomplete documents, ensuring safe and effective maintenance of your chainsaw․ The Stihl MS170 parts diagram PDF is organized into sections, including exploded views, parts lists, and assembly guides․ Use bookmarks or the table of contents to quickly locate specific components․ Zoom in for detailed views of intricate parts․ The search function can help find part numbers or descriptions․ Each diagram includes labels and reference numbers, making it easier to identify and cross-reference components․ This structured format ensures users can efficiently navigate and understand the document for maintenance or repair purposes․

The Stihl MS170 is a popular chainsaw with common questions about its maintenance, parts replacement, and troubleshooting․ Users often inquire about chain tensioning and fuel system issues․ Common questions about the Stihl MS170 include inquiries about chain tension, fuel mix ratios, and troubleshooting startup issues․ Users often ask how to identify worn parts using the parts diagram and where to find genuine Stihl components․ Additionally, many seek guidance on routine maintenance tasks, such as cleaning the air filter and inspecting the muffler․ These FAQs highlight the importance of referencing the parts diagram for accurate repairs and ensuring the chainsaw operates efficiently․ Regular maintenance is crucial for longevity and performance․ Some users believe the parts diagram is unnecessary for minor repairs, but it’s crucial for accuracy․ Others think all parts are interchangeable with similar models, which isn’t true․ Many assume DIY repairs save money, but incorrect installations can damage the saw․ Another misconception is that the PDF diagram is hard to navigate, but it’s designed for easy reference․ Always verify part numbers and follow the diagram to avoid costly mistakes and ensure safety․ Proper use of the diagram prevents errors and extends the tool’s lifespan․ The Stihl MS170 parts diagram PDF is a vital tool for maintaining and repairing your chainsaw․ Regular use ensures optimal performance and extends its lifespan․ For optimal use of the Stihl MS170 parts diagram PDF, always cross-reference part numbers with the catalog․ Understand the exploded views to identify components accurately․ Regularly check for updates to ensure you have the latest version․ Use the diagram alongside the operator’s manual for comprehensive maintenance․ Familiarize yourself with symbols and abbreviations used in the document․ This will help you navigate and utilize the resource efficiently, ensuring your chainsaw operates at peak performance․ Regular maintenance is crucial for extending the lifespan of your Stihl MS170 chainsaw․ Use the parts diagram PDF to identify and replace worn components promptly․ Check the fuel system, chain tension, and lubrication regularly to prevent damage․ Schedule routine inspections using the maintenance guide outlined in the PDF․ Addressing issues early ensures reliable performance and safety․ By following the diagram and maintenance schedule, you can avoid costly repairs and keep your chainsaw operating efficiently for years․ Proper upkeep also enhances safety and productivity during use․

Using the Parts Diagram for Maintenance

4․1 Identifying Wear and Tear Parts

4․2 Scheduled Maintenance and Replacement

4․3 Troubleshooting Common Issues

Repair and Replacement Guidance

5․1 Step-by-Step Repair Instructions

5․2 Tools and Resources Needed

5․3 Safety Precautions During Repair

Ordering Genuine Stihl Parts

6․1 Finding Genuine Stihl Dealers

6․2 Ordering Parts Online

6․3 Verifying Part Numbers

Exploded View of the Stihl MS170

7․1 Visual Representation of Components

7․2 Assembly and Disassembly Guide

Parts List and Catalog

8․1 Comprehensive Parts Catalog

8․2 Cross-Reference Guide

Operator’s Manual and Safety Guidelines

9․1 Safety Tips for Handling Chainsaws

9․2 Pre-Operation Checks

9․3 Storage and Transportation Tips

Downloading the Stihl MS170 Parts Diagram PDF

10․1 Official Sources for the PDF

10․2 How to Navigate the PDF Document

Common FAQs About the Stihl MS170

11․1 Frequently Asked Questions

11․2 Common Misconceptions

12․1 Final Tips for Effective Use

12․2 Importance of Regular Maintenance